Vibrational Frequency Used as Internal Clock Reference to Access Molecule-Metal Charge-Transfer Times – Publication by A3 (Jakob)

Peter Jakob and Sebastian Thussing derived ultrafast charge-transfer times at molecule-metal interfaces using the vibrational oscillation period as an internal clock reference

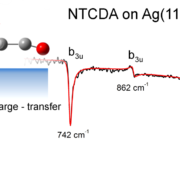

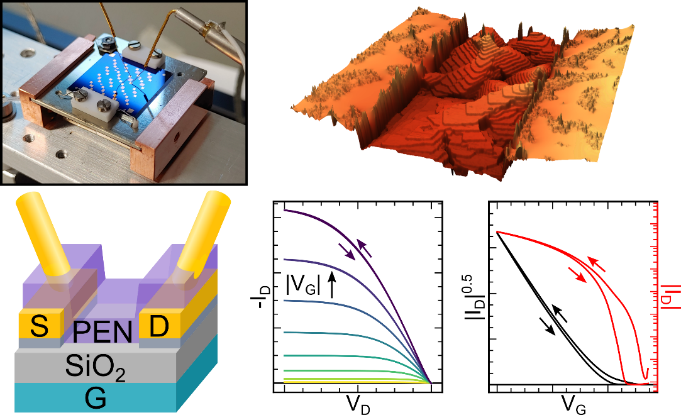

Interfacial dynamical charge transfer at the molecule-metal interface, associated with non-adiabatic electron-vibron coupling leads to vibrational bands displaying characteristic asymmetric line shapes. Copyright by SFB1083.

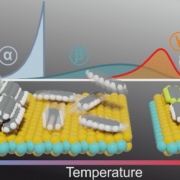

Dynamical charge-transfer processes at molecule-metal interfaces proceed in the few fs timescale that renders them highly relevant to electronic excitations in optoelectronic devices. This is particularly true when electronic ground state situations are considered that implicate charge transfer directly at the fermi energy.

Prof. Jakob and Dr. Thussing showed that such processes can be accessed by means of vibrational excitations, with nonadiabatic electron-vibron coupling leading to distinct asymmetric line shapes. Thereby the characteristic timescale of this interfacial dynamical charge transfer can be derived by using the vibrational oscillation period as an internal clock reference.

Publication

P. Jakob, S. Thussing

Vibrational Frequency used as Internal Clock Reference to access Molecule — Metal Charge Transfer Times

Phys. Rev. Lett. 126 (2021) 116801 DOI:10.1103/PhysRevLett.126.116801

Contact

Prof. Dr. Peter Jakob

Philipps-Universität Marburg

SFB project A3

Tel.: 06421 28-24328

EMAIL